The inspection of industrial equipment is a method of inspection that aims to maintain the production of industries in an optimized way, as the technique aims to always keep in good condition the machines used every day by the factories. But for this to be done correctly, a frequent maintenance analysis of all the processes involved in the system is mandatory. Exactly for this reason, the service of industrial equipment inspection is essential and must be done constantly, if one aims to eliminate hazards and work accidents in the service area of your industry.

Industrial equipment inspection has a very comprehensive way of being developed. Main methods of its practice are listed below:

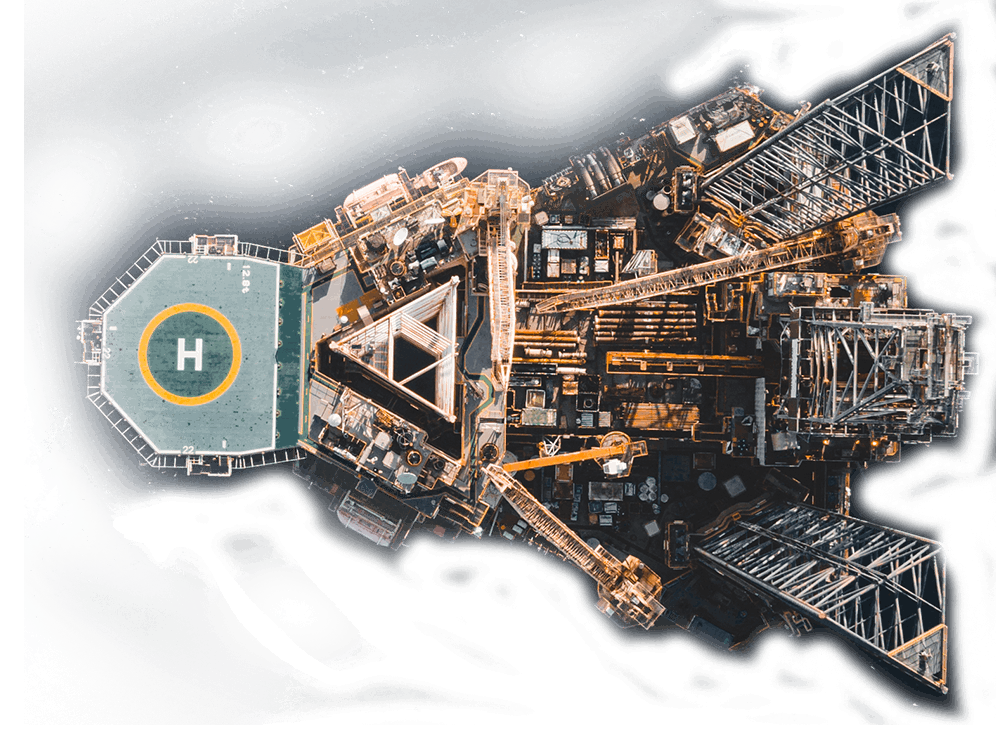

- Inspection of static and rotating industrial equipment;;

- Inspection of electrical systems and machines that are connected to this type of assembly line;

- Inspection of piping systems and product manufacturing equipment;

- Organization of technical measures, which maintain service justification and prevent possible equipment defects.

Since each piece of equipment has different identification measures, another fundamental aspect is to be aware of how to analyze the most perfect ways to inspect industrial equipment. Each inspection carries with it, its own characteristics and it is necessary analysis and technical knowledge to execute them. As each step of this process is complex, it is indicated that a specialized company takes care of the ways to complete the entire work.