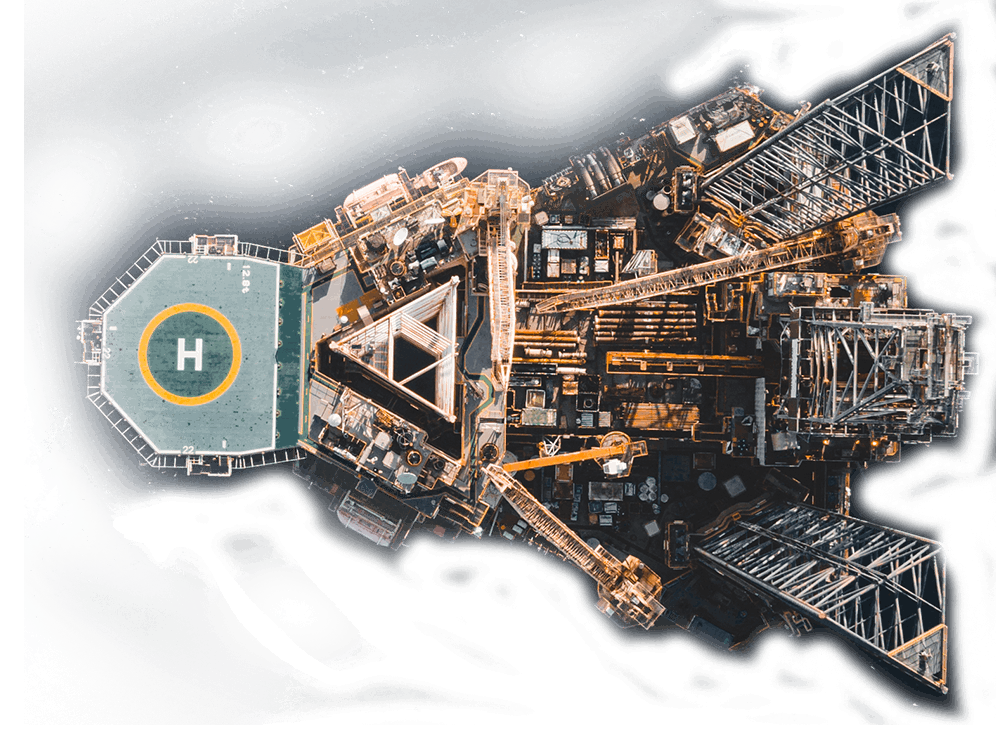

Techocean is highly experienced in the manufacturing of metal structures. Our productive capacity includes a wide variety of structures already made for several clients.

We have a structure capable of meeting large project demands, having as our main facility a 1300m² shed for the execution of boiler, welding and machining services, a 500m² blasting and painting shed, and a total area of approximately 10,500m².

Our manufacturing process meets all applicable standards, including the application of load testing and non-destructive testing. We have manufacturing capacity in several carbon steel alloys, stainless steel and aluminum.

Counting on a highly capable structure for the elaboration of large piping layouts and structures in general, we provide our customers with unique and complete manufacturing solutions, making available all the metallic alloys used as raw material for the operational lines both in the production and drilling segments, from carbon steel ASTM A-106 GR.B, ASTM A-36 to special alloys such as API 5L, ASTM AH-36, DH-36, EH-36 and others, as well as stainless steel alloys 316 and 316L and special alloys such as DUPLEX and SUPER DUPLEX.

We perform our tests in compliance with all the respective applicable standards, also relying on highly qualified and recognized partners in the national market for the execution and certification of pressure tests and other required tests. All our pipes are duly monitored by dimensional inspectors and NDT, and their delivery is made upon prior approval by the customer according to the isometric design and modeling developed by our engineers.